Why have PE pipes become the new favorite for water supply projects?

2021-11-12

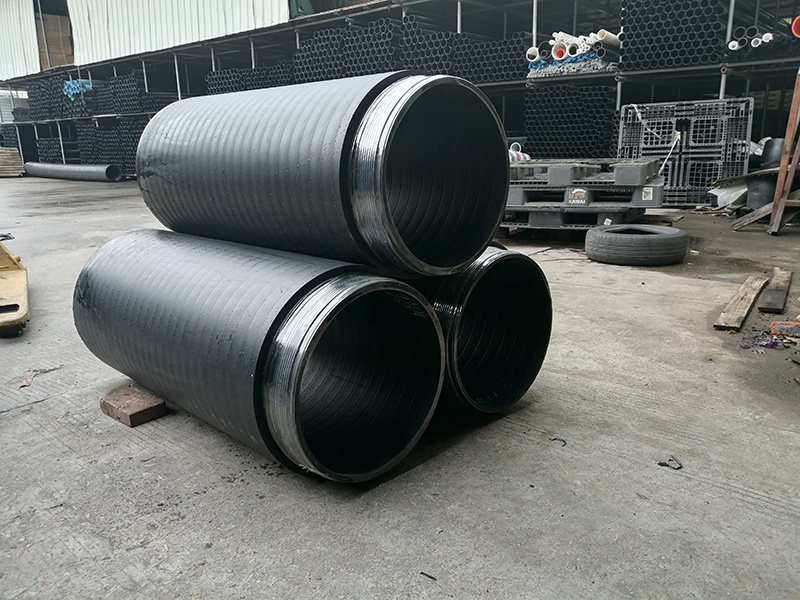

In recent years, with the rapid development of plastic pipe technology, PE pipes have gradually become a leader in the field of building water supply pipelines due to their excellent product performance. Compared with traditional galvanized pipes and cast iron pipes, PE pipes not only overcome the disadvantages of easy rust, scaling, bacterial growth, and short lifespan, but are also highly regarded for their reliable quality, safe operation, easy maintenance, and cost-effectiveness. It is particularly worth mentioning that its unique hot-melt process is very suitable for the direct burial and concealed burial of pipes, effectively solving the problem of joint leakage. Because of this, PE pipes have stood out in municipal water supply projects and become the preferred pipe material for "replacing steel with plastic".

|

|

1. Excellent Physical Properties

PE pipes combine the hardness and toughness of high-density polyethylene, while also exhibiting excellent flexibility. In addition, its hot-melt connection performance is also excellent, bringing great convenience to the installation of plastic pipes.

2. Excellent Sanitary Properties

PE pipes not only have excellent physical properties but also exhibit excellent sanitary characteristics. Their non-toxic, odorless, and environmentally friendly properties have led to their widespread use in drinking water transportation and food processing.

PE water supply pipes, as a non-polar high-polymer material, stand out in the field of drinking water transportation due to their unique properties. They do not contain heavy metal salt stabilizers, ensuring the material is safe and non-toxic. At the same time, their good antibacterial properties and odorless characteristics make them an ideal choice for drinking water transportation.

3. Excellent Abrasion and Corrosion Resistance

PE water supply pipes are not only safe and non-toxic but also perform excellently in abrasion and corrosion resistance. Their unique non-polar high-polymer structure gives them excellent durability, able to withstand the erosion of various corrosive substances, ensuring long-term stability. At the same time, their abrasion resistance allows them to maintain excellent performance during transportation, reducing the need for replacement due to wear.

PE pipes perform particularly well in terms of abrasion resistance, with an abrasion coefficient as high as four times that of steel under normal conditions. In addition, it also has excellent corrosion resistance, able to withstand the erosion of various chemical media except for a very small number of oxidants.

4. Convenient Connection and Simple Construction

PE pipes demonstrate great convenience in terms of connection, and their construction process is relatively simple, with various methods, saving a lot of time and cost for engineering projects.

PE pipes have a lightweight pipe body, making handling convenient. Their connection methods are flexible and diverse, reducing the number of welded joints and simplifying the operation process. When laying long-distance pipelines, the coil laying technology can be fully utilized to further improve construction efficiency. In addition, the excavation requirements for PE pipe trenches are more relaxed than those for steel pipe trenches, providing more possibilities for operations under restricted construction conditions. Furthermore, electrofusion welding technology can also be used when necessary, further enhancing its construction adaptability.

5. Lightweight Material, Economical and Practical

PE pipes are known for their lightweight properties, weighing only one-tenth of steel, greatly reducing the burden on workers during construction and thus lowering construction costs. In addition, if small-diameter pipes that can be coiled are selected, engineering costs can be further reduced to a certain extent.

6. Strong Durability and Easy to Recycle

PE pipes stand out for their excellent durability and environmental characteristics. They have a lifespan of up to 50 years and are easy to recycle, ensuring that no environmentally harmful substances are produced. In addition, the technology is quite mature and continues to improve. Choosing Yuantong PE pipes, you will enjoy the solid guarantee of five reasons: First, the new PE100 grade polyethylene particles used are all from high-quality new raw materials, with absolutely no recycled materials mixed in, guaranteeing no odor.

Previous page:

Contact us

Email:

xucipeng163@163.com

Mobile:

+86-139-2217-2108

Company address:

Haoliang Industrial Park, Longtang Town, Qingcheng District, Qingyuan City, Guangdong Province

Service hotline:

Service mailbox:

5-year warranty commitment, lifetime technical consultation - Lianhong Pipe Industry, making pipes the most reliable silent partners

HUATAO GROUP

Online message to get application solutions for free

Copyright © 2025 Guangdong Lianhong Pipe Industry Co., Ltd.